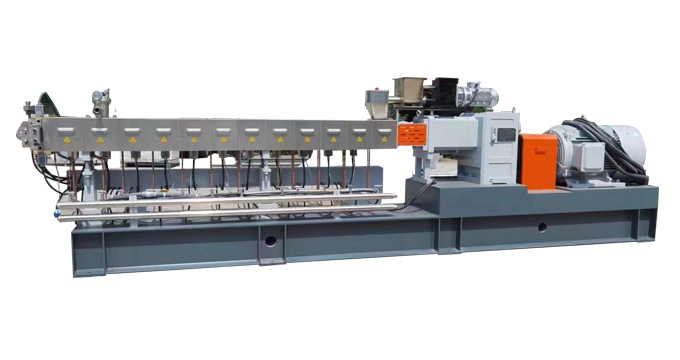

Twin Screw Extruder

GD’s Twin Screw Extruder Machine with excellent dispersing and compounding for all the materials, is widely used for plastic compounding, pharmacy, chemicals, and food extrusion. As one of the leading professional suppliers in China, GD EXTRUSION has over 25 years intensive experience in twin screw design and manufacture.

Applications

Colour Masterbatch

Mono-colour (high dosing) colour concentrate colour masterbatches, Single Pigment Concentrate Colour Masterbatches, Customized Colour Masterbatches. It is widely used for plastic colour matching productions GD has intensive experience & twin screw compounding solutions for your colour masterbatches production.

Additive Masterbatch

Whenever it comes to modifying plastics with special additives so that they are functionally accurate, GD experts will give you more advice on how to make good quality additive masterbatches. Delivered as additive powder blend, compact or compounded into a plastic matrix. Gravimetric dosages for solids and liquids, side dosages and gear pumps allow a wide variety of formulations to be perfectly fed into the carrier polymer. UV stabilizers┬increase light resistance Thermostabilizers protect your plastic from thermal, mechanical and chemical influences Anti-slip roughs the surface of films Antiblock gee for adhesive-free film surfaces and to avoid nozzle deposits Lubricants and internal lubricants to improve flow behaviour Demoulding aids.

Filler Masterbatch

Filler masterbatch normally divided into CaCo3 filler, talc filler, Kaolin filler, TiO2 filler, BaSo4 filler,etc. They are widely used in plastic industries. It is used for cost effective,and also it can modify the product properties to some extend. GD will help you to give the best suitable solutions for the filler masterbatch extruder.

Thermoplastics

Thermoplastics are widely used in various plastic industries, like automotive, toys, cables, wrapping, shoes, pipes, transportation, construction, etc. Almost all of them could be process on twin screw extruder, such as TPR, TPU, TPE, POE, TPO, EVA, PA hot melt, etc. GD has too much experiences on thermoplastics processing know-how.

Engineering Plastics

Engineer plastic is popular use in, automotive, home appliance, electrics, engines, boat,airplane,etc. We provide twin screw compounding solutions for engineering plastics, PC/ABS, PA, PP, PBT+glass fiber/carbon fiber, etc.

BIO-Degradable Materials

Biodegradable materials are a type of biomaterial. They are used to provide a specific application within the body and subsequently degrade over a given time.GD have exclusive solutions for bio-degradable compounds on PLA, PBAT & PVA. Get to us for valuable advice on your applications.

Twin Screw Extruder Features

TSE-C Twin Screw Extruder

Maximum screw speed: 600rpm.

Various electric control systems.

Multi-pelletizing systems.

Competitive performance/price ratio.

Model | TSE20 | TSE35C | TSE40C | TSE52 | TSE65C | TSE75C | TSE95C |

Screw Diameter (mm) | 22 | 36 | 41 | 51.5 | 62.4 | 71 | 93 |

Screw Speed (rpm) | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

Motor Power (kw) | 4 | 15 | 30 | 55 | 90 | 132 | 315 |

L/D Ratio (Max.) | 60 | 68 | 68 | 68 | 68 | 68 | 68 |

Output (kg/hr) | 5-15 | 20-80 | 50-150 | 150-250 | 200-400 | 350-650 | 800-1500 |

TSE-D Twin Screw Extruder

Newly designed high torque gearbox, specific torque up to 13N.m/cm3.

Max. screw speed: 900rpm.

Uniform process for the screw and barrel in good geometry.

Efficient lubrication system for the gearbox.

Reliable safety clutch and interlock system enables the fast disconnection, protecting the machine.

Optimized screw profile, enables one machine for multi-application.

Model | TSE40D | TSE52D | TSE65D | TSE75D | TSE95D |

Screw Diameter (mm) | 41 | 51.5 | 62.4 | 71 | 93 |

Screw Speed (rpm) | 600-900 | 600-900 | 600-900 | 600-900 | 600-900 |

Motor Power (kw) | 55 | 90 | 160 | 280 | 550 |

L/D Ratio (Max.) | 68 | 68 | 68 | 68 | 68 |

Output (kg/hr) | 150-250 | 200-400 | 400-800 | 1000-2000 | 1500-3000 |

Twin Screw Extruder Screw Configuration

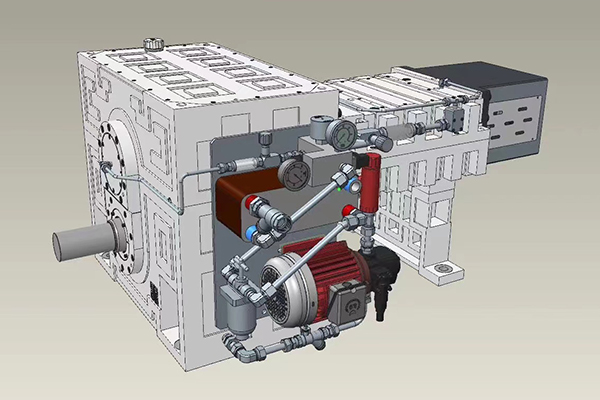

High torque gear box

GD applies high torque gearbox for TSE-D twin screw extruders. The quality and durability are more convincing to our customer who requires higher standard twin screw extruders for their application. There are some trustable and famous good quality gearbox brands we have cooperated with, in local also we can provide original import gearbox such as Zamebllo, Henschel, PIV, etc.

Screw and barrel

The HIP material, which originated in Germany or the USA, is 4 times more wear-resistant than that common metals. In order to meet the requirements of good durability of screw and barrel, some higher quality materials will be used in our TSE-D twin screw extruder as well as TSE-C twin screw extruder to make the screw and barrel more wear-resistant, reduce the replacing time for the customer which can enable customer not only running the machine continuously but also save the maintenance time.

Safety Clutch Torque Limiter

With high-quality gearbox, the safety clutch is a must for the extruder. The quality, accuracy, torque and action time of Europe origins safety clutch are excellent enough to make sure your twin screw extruder is well protected when gets emergency incidents.

Customized Screw Profile

To make excellent masterbatches, mixing and dispersion is the critical factor. While the twin screw profile design determines the effect of mixing and dispersion of different components. GD professional technicians will give you a perfect screw profile design specially for your specific applications.

Efficient Driving System

As the energy crisis all over the world is facing, GD has dedicated its best to save energy by using different efficient heating systems for your extruders.

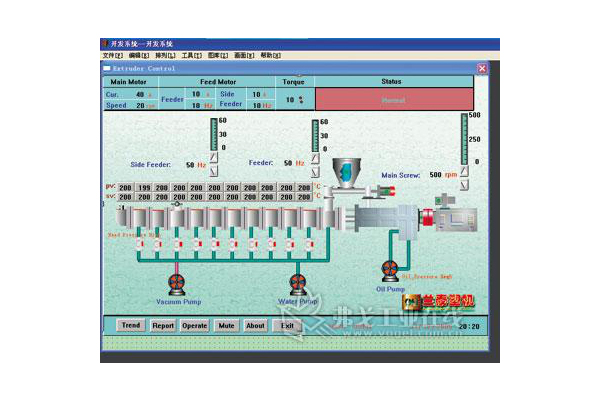

Smarter Control System Under Industrial 4.0

GD has smart HMI monitoring & controlling system for the whole system without pushing different buttons and without any records. A remote control function enables GD to help from the office to solve the issues. In this system, the screw speed, feeding rate, cooling, heating, etc will be controlled and monitored absolutely accurate. What’s more, you can save your different formulas and the operation data there, next operation will be easily taken out without resetting all.

Types Of Twin Screw Extruders

In order to meet the different requirements of the market, we provide two different types of twin screw extruders. Customers can choose the best suitable twin screw extruder based on their needs and applications.

Get In Touch

If you would like to have a question then get in touch today, we are ready to assist 24/7.

We welcome your cooperation and we will develop with you.

-

- About

- Products

-

contact us

Tel: +86 13851443003

Tel: +86 13851443003  Whatsapp: +86 13851443003

Whatsapp: +86 13851443003  Email: [email protected]

Email: [email protected]  Address:Ningmao Road,Guozhuang,

Address:Ningmao Road,Guozhuang,Jurong,Jiangsu province.

Copyright © 2024 NANJING GUANGDA INTERNATIONAL GROUP CO.,LTD. All Right Reserved